Automated End-of-Row Turns a Must for Large Potato Contractor

May 2, 2019

Ben Clappison farms over 4000 acres of potatoes on a contract basis in the United Kingdom. With the cost of planting, growing and harvesting speed potatoes averaging about £2000/acre, it is crucial for his beds to be planted as accurately as possible. If they’re too wide, he’s wasting soil and if they’re too narrow he won’t maximize his yield potential.

Achieve Precision-Level Accuracy by Upgrading an Older Machine

In 2018, Ben decided to invest in a tractor for his cultivating and potato bed forming operations. After evaluating both new and older tractor options and finding the cost of a new, guidance-equipped tractor to be prohibitively expensive, he decided to purchase a 2010 Case 485 STX Quadtrac that he could then outfit with new guidance technology.

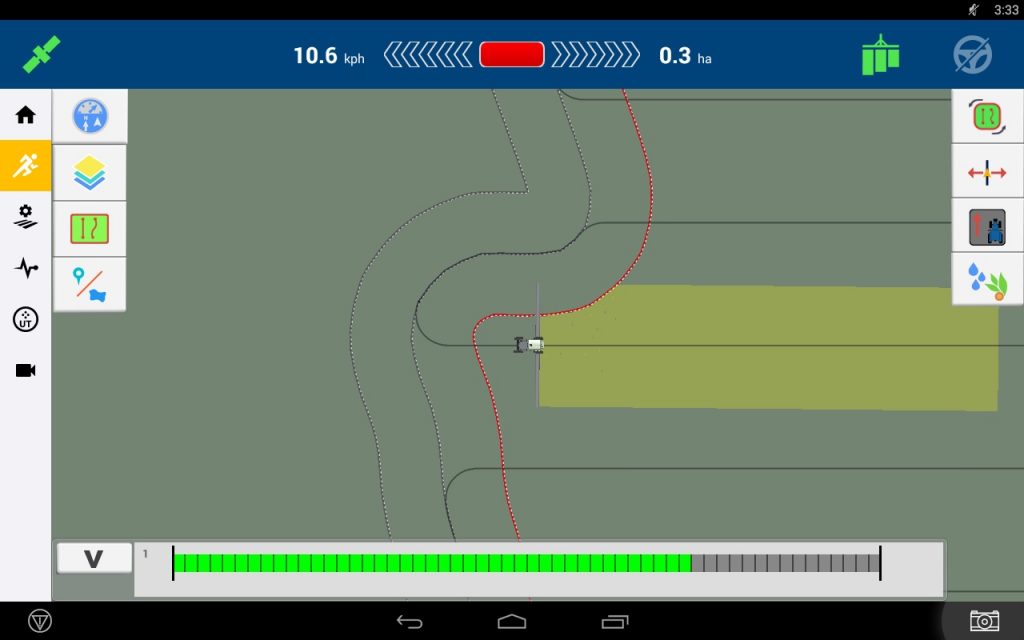

Much of the bed forming work that Ben does requires the ability to cultivate down to 2ft/60cm deep. At this depth, the implement width is relatively narrow and as a result, many turns are made in the field. With these challenges in mind, he tried NextSwath to give him the control and ability to make very tight turns that could never be made effectively if done manually. After a successful trial, he was happy with the results and ultimately chose the GFX-750 display system to achieve the level of accuracy he needed in his operation.

How Trimble® NextSwath™ Works

When approaching the end of a crop row, the NextSwath technology will automatically calculate and execute the best possible path to turn around the vehicle and approach the next crop row or swath. Users working with a towed implement can also enable the option to optimize the turn for the implement position. By automating the turning process, the NextSwath solution can:

- Dramatically improve the operator’s performance

- Eliminate towed implement undershooting or overshooting

- Minimize skips and overlaps when lining up for the next row.

This improved turning efficiency and repeatability can increase yield while also saving time and fuel costs, and preventing crop damage.

Reliable Accuracy at All-Hours

In early Spring, Ben can expect to work 110-120 hours per week with the end of his days regularly going until midnight and the early hours. NextSwath offers the ability for him to just keep going when he needs to with confidence to know that he can work tight to the hedge and field boundaries.

“It’s so consistent at the ends with the turns. It’s beyond belief, the best GPS system I’ve used and it’s just so consistent on your headland…it’s just so easy to use as well, and far easier to set up than the Deere system” – Ben

Prior to using the GFX-750 display system with CenterPoint RTX, Ben relied on RTK working on a mix of fixed and mobile bases.

“I’m so impressed with RTX, it’s just as good as RTK I find. Not having to set up mobile-bases and changing between fixed base stations saves time. The GFX converges on the way to the field in less than two minutes. If I leave the field overnight the line is exactly where I left it the day after.” – Clappison

Learn More About the GFX-750 display system

Whether you’re thinking about upgrading an older tractor or taking your operation to the next level, learn more about GFX-750 display system.