What Is Precision Ag?

Precision agriculture (PA) can be an intimidating topic.

High-tech terms like drones, robots, sensors, geo-mapping and big data come up when discussing precision ag. Not only are those concepts misunderstood and complex, but they all come with price tags— and often large ones.

All of this complexity and expense have led to the relatively slow adoption of many PA practices on farms across the United States. However, in recent years, growers big and small have started tapping into the emerging potential of PA.

According to a 2016 United States Department of Agriculture report:

- GPS-based mapping systems, including yield monitors, are used on about 50 percent of all corn and soybean farms in the U.S.

- Guidance and auto-steer systems have been adopted by approximately 33 percent of corn and soybean farms

- Soil mapping using GPS coordinates and variable rate technology for applying inputs are used on 16 to 26 percent of these farms.

In 2017, 261 Canadian farmers participated in a precision ag survey conducted by Agriculture and Agri-Food Canada. 65% of participants said they strongly agree that PA is useful, while 70% of participants said they use farm management software on their computer.

In 2017, 261 Canadian farmers participated in a precision ag survey conducted by Agriculture and Agri-Food Canada. 65% of participants said they strongly agree that PA is useful, while 70% of participants said they use farm management software on their computer.

The survey participants ranked how important certain reasons were for using precision ag on the farm. ‘Better crop management,’ ‘improved equipment and labor ’ and how to ‘reduce crop input costs’ were ranked as the top three reasons for adopting PA.[1]

What is Precision Ag?

Before we delve into the specifics of PA, let’s define it. The primary goal of precision agriculture is to strive for profitability, efficiency, and sustainability on the farm. This is achieved through a combination of PA technology and PA equipment. First, PA technology gathers and analyzes data from every action performed on your operation and helps guide both your immediate and future decisions: what seed to plant in what field, or where exactly you need a precise amount of fertilizer or chemical. Then, once you have an idea of what needs to be done on your farm, PA equipment puts your plan into action. For example, you can prep your land by using automatic section or variable-rate application control. Or, you can precisely maneuver your tractor and implements using a hands-free steering system, like the Autopilot™ Automated Steering System. And, with the right farm management software, you can manage complex prescriptions across a variety of productivity zones all in one platform.

The PA movement started in the 1990s with the introduction of Global Positioning Systems (GPS) and Geographic Information Systems (GIS). A wide range of sensors, monitors, and controllers were also developed during that time and were used on ag equipment like shaft monitors, pressure transducers and servo motors[2]. With the rapid introduction and adoption of mobile computing, high-speed Internet and reliable satellites, the reach and usage of PA has grown immensely over the past decade, so much so that it now touches almost every area of a farm operation.

Why Invest in Precision Ag?

When your hardware and software can communicate with one another, you won’t have to spend as many late nights planning your next steps—the capabilities of precision ag will manage it for you. By improving your overall efficiency, you can have more meals at home with your family and make it to more family events and get-togethers. The ripple effect of precision ag moves beyond your operation, giving you more than just monetary value.

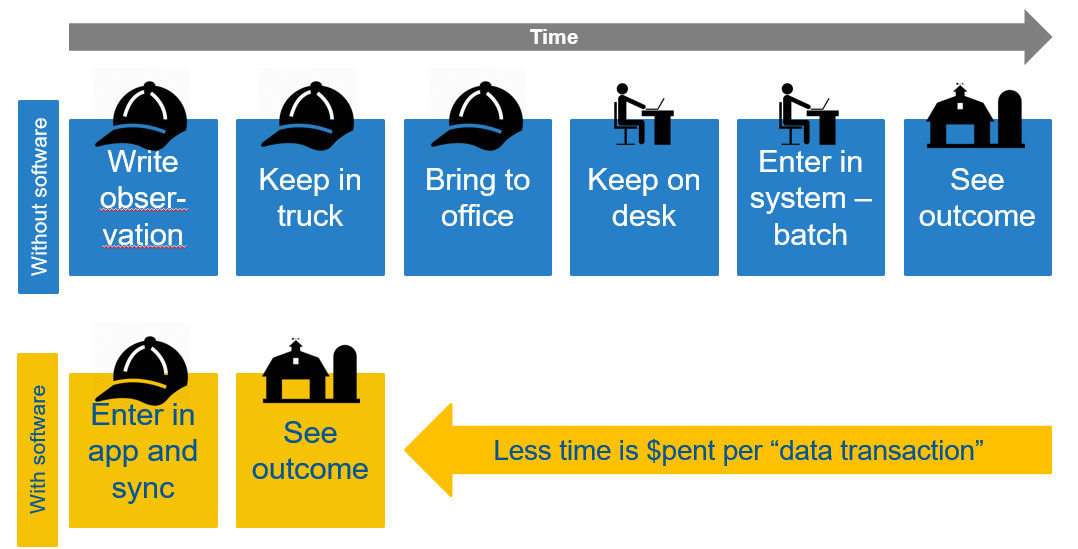

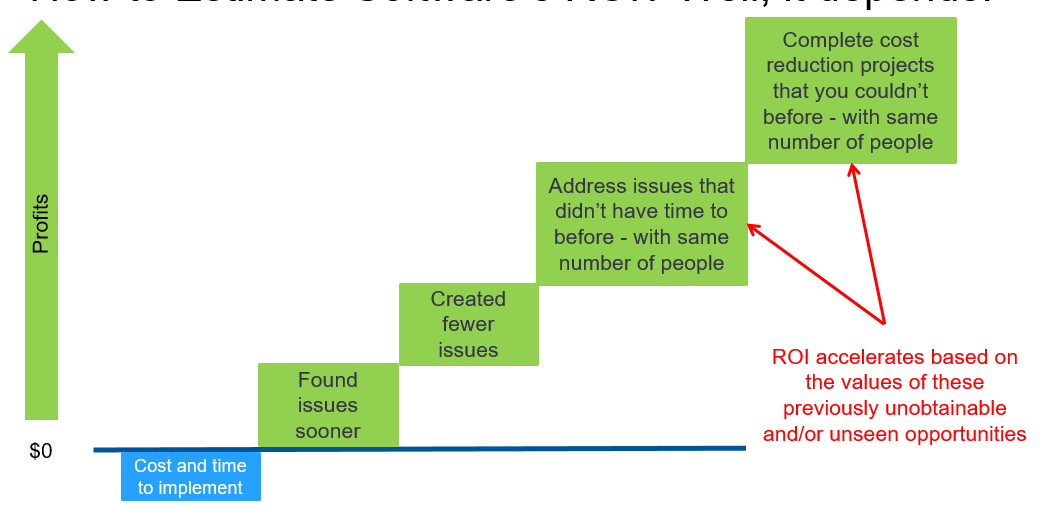

But that doesn’t mean PA won’t help your bottom line. There is a cost and time savings benefit for your farm that can be realized through implementing PA. Studies show that return on investment (ROI) in PA varies depending on numerous factors like the type and size of your farm, specific technology introduced and how the data is analyzed and implemented.

However, when PA is introduced correctly and is part of an overall plan, various research studies show that PA technologies can quickly reduce labor and crop input costs, cut back your water usage and save you time and headaches when planning and executing each growing season.

The most important thing to know is that PA is not a one-size-fits-all solution. What works for your neighbor might not make sense for you. Looking at each operation individually and implementing solutions that work for your particular farm is the only way to use PA successfully and receive a positive ROI.

It’s the technology that ties your whole farm together, giving you the control and visibility you need to make better decisions. When you’re able to make better decisions, you know you’re getting the most out of your operation, giving you peace of mind and renewed confidence.

5 Tips to Help You Succeed with Precision Agriculture

Trying to decide which PA technologies are right for your farm can seem like an intimidating task. However, the solutions incorporated into your farm can be simple and should make sense for your operation. If you go into PA with the right attitude, you can be successful and see a significant return on your investment.

- Start with a goal

Whenever you make an investment in your operation, it should be a part of your overall business plan and solve a problem where you currently have no solution. Creative problem-solving is something that has been done on the farm for centuries. But now, the solution is often found within a piece of technology rather than in the shop.

- Understand the management and maintenance required

Good technology should work for you. If you’re going to spend the money on new seeding, spraying and harvesting monitors, you need to calibrate the machines regularly, organize the data, ensure it’s accurate and then act on what the data tells you.

Just like any piece of equipment on your farm, PA technologies need to be maintained in order to maximize their full potential.

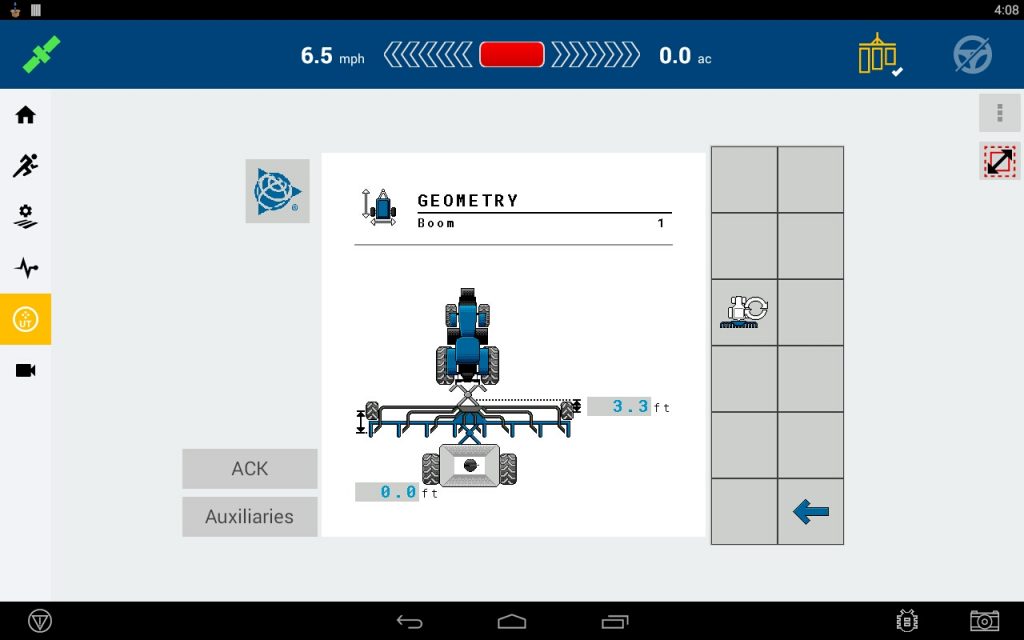

In addition, it’s important to understand how different PA technologies can work together in order to give you the best results. For example, a seed monitoring system like the Field-IQ™ Crop Input Control System can be used in conjunction with a guidance display system like the GFX-750™ Display or the TMX-2050™ Display. When used together, you can accurately monitor and map your fields in real-time and correct problems as they arise. You can also simplify precision ag data management by using features like Autosync™ that connects to other data sources.

- Don’t be afraid to make mistakes

As long you’re making PA decisions based on data and not on emotion, any missteps should be small and learned from quickly. In fact, much of the success of using PA technology is accomplished through trial and error. Recognizing the error and making adjustments in the moment will ensure your PA technologies are accomplishing their goal of increased efficiency and productivity.

- Have a support network

Making the correct PA decisions for your farm is not easy—especially the first ones. Having solid support from a Trimble Vantage Reseller can be a great help when you make the initial investment, as you evaluate your data each season and when you expand the technologies used in your operation.

- Get connected

The web is an incredibly powerful tool to find other farmers who are making similar decisions on their farm. Web platforms like YouTube and Twitter can greatly expand your support network. It’s a great idea to search for reviews and testimonials before you invest in a certain piece of technology. Farmers around the world post online reviews that offer the pros and cons of various equipment and products—which is invaluable and free.

So now that you’ve got the right PA mindset, let’s explore some of the most popular technologies available.

Guidance & Steering Systems

Some of the first and most widely used PA technologies on farms across the U.S. were GPS-guided combines, tractors, sprayers, and seeders.

High-precision guidance and steering provide outstanding accuracy when working in the field, allowing growers to work anywhere, any time and in all conditions, even at night.

One of the largest benefits of guidance systems is the reduction in the amount of overlap and/or skips within the field, saving you fuel and time while dramatically lowering your stress levels behind the steering wheel.

The improved accuracy in the field also ensures you’re seeding and spraying efficiently. A 2009 study from Virginia Tech University estimated a range in savings of 2-7 percent (with an average of 5 percent) in input costs due to GPS guidance systems.

Looking at specific guidance systems, there are a few to choose from:

- Assisted steering systems provide you with a path to follow in the field. This results in more accurate driving, however, you still need to control the steering wheel.

- Automated steering systems are in full control of the steering wheel, allowing you to take your hands off the wheel during trips down the row and keep an eye on the planter, sprayer or other equipment. For example, the Autopilot™ Automated Steering System can help you complete your field applications quickly and accurately. By using terrain-compensation technology, it remains highly accurate, even on difficult terrain. It can also be used with the TMX-2050™ Display, sharing your data between your hardware and software and keeping them connected with one another.

- Intelligent guidance systems provide different steering patterns depending on the shape of the field and can be used in combination with the above systems. These are extremely helpful systems when working on an irregularly-shaped field.

- Implement guidance systems ensure that your tractor and implement are working together, even when your hands aren’t on the wheel. Systems like the actively control your implement so you don’t have to. The implement is able to correct its position without input from the tractor and keeps them both on the same guidance line.

Land Preparation

Preparing your land each growing season is a delicate balance between things you can and cannot control. Even when we do everything right, it can all be wiped out if the rain clouds stay away. While PA doesn’t erase that volatility, it does give you a few more tools to successfully handle the variables that are out of your control.

Before making any decision, you’ll need to know what’s going on in your soil.

Random soil sampling is the traditional approach that works best for uniform fields with little variation, while managed random sampling looks at soil from average production areas. This approach is different from random sampling, which provides an average of all cores taken throughout your field. Managed random sampling is recommended if you can’t identify a dominant production area on your field.

Benchmark sampling is suggested for fields with more variability (hills, depressions, etc.). Benchmark sampling reduces the variability of a field by reducing the area sampled. A small area representing the majority of the field is sampled the same number of times as in random sampling.

Beyond soil sampling, another new source of data to help with land preparation is imagery from aerial field views. With infrared images of your field, you can quickly identify problems that you simply can’t see from the ground.

Because of the intricacies involved, teaming up with your local Trimble Vantage Reseller is recommended when it comes to soil sampling, mapping and interpreting the results. While soil sampling is not an exact science, understanding the condition of your soil will help you determine how to prepare your fields for a growing season.

PA equipment is particularly valuable in strip till and anhydrous application. Guidance display systems enable you to accurately monitor and map field information in real-time, with a wide array of functionalities to suit different farming needs. Tractor, implement and row guidance steering systems minimize skips, overlaps and guess rows, incorporating terrain compensation technology to maintain precision in difficult conditions.

Yield Monitoring

A strong addition to any PA strategy is yield monitoring. Introduced in the early 1990s and working in conjunction with GPS technology, the use of yield monitoring equipment has increasingly become a conventional practice in modern agriculture.

Information like seed varieties, moisture, grain loads and auto-cut width are gathered by the yield monitor and shown on a display in the cab. This can help you make in-the-moment decisions in the field that might not be apparent with the naked eye.

When you take all this information and format it into a yield map, it becomes a powerful tool that can inform all your operational decisions going forward. Combined with your cost of production and application maps, a yield map will show you what areas of your farm are more profitable than others and should help you bring other areas of your field up to par. You can go one step further with farm management software that provides ‘Profit Maps’ so you can deep-dive into each field and see what strategies are working.

Variable Rate Technology

Armed with your yield monitoring data, you’re now ready to unleash the PA power of variable rate technology (VRT). VRT is the ability to adapt parameters on a machine to apply seed, chemical or fertilizer according to the exact variations in plant growth or soil nutrients and type. VRT can be adapted to crop sprayers in either an individual nozzle or section (a set of nozzles). Planters with VRT usually have the automatic controllers on individual rows. Solutions like the Field IQ™ ISOBUS Liquid control system and the enable you to control the amount of liquid that’s being applied on your operation, reducing your input costs, and creating a high-yielding environment for your crop.

So, instead of applying a uniform amount of seed on one field, VRT allows you to apply the optimum type and amount of seed in a specific area of any field—either automatically or manually right from the cab. You can also avoid double coverage and eliminate wasted inputs.

Another huge bonus is that you’ll have a complete record of all inputs used in your operation, helping you make future decisions.

Is VRT Worth the Investment?

Like all PA technologies, it depends on how it’s used. When used alongside soil sample data, aerial maps and yield monitoring, VRT is extremely effective at ensuring your inputs are being applied to your fields as effectively as possible.

While it often takes some trial and error, if you’re committed to the PA process, you should experience a fast return on your investment.

Flow & Application Control

By managing the flow and application of inputs on your operation, you can precisely apply inputs where needed on your field. Seed monitoring systems are especially helpful during planting; you need to know when you’re experiencing planting issues like skips, doubles and failed unit rows. But, you can’t fix what you don’t know. Fortunately, a seed monitoring system, like the Field-IQ™ Crop Input Control System, sees what you can’t.

You can monitor your seeding information or fertilizer delivery lines in real-time. It allows you to control your variable-rate application and helps you keep an eye on your automatic section control. It also prevents costly planter problems by catching them early before they impact your yields. When used in conjunction with a guidance display system—like the GFX-750™ Display or the TMX-2050 Display—you can accurately monitor and map your fields in real-time and correct problems as they arise.

At a single glance, you should be able to see where your fields are making you money and where inputs are not paying off. Precision ag is a farm management strategy, one that is best evaluated using profit maps over the long-term.

Water Management

As we’ve all experienced firsthand, water is a scarce resource, especially in drought conditions. A precision farm irrigation system is one way to mitigate issues that come up when rain clouds don’t appear. But when it does rain, you can’t always monitor your fields in-person. That’s where PA software solutions can get the job done for you.

When managing water, factors like precipitation, irrigation and soil moisture contribute to available water for your crops, which in turn impacts your yields. But your yields are also affected by additional factors like topography and soil type. Visual surveys of your field can easily identify any obvious red flags like erosion and depressions where ponding occurs. Using GPS tools like WM-Survey with RTK accuracy are crucial for identifying steep slopes, rises and low spots that can impact your yields.

Or, you can use the VerticalPoint RTK™ Grade Control system on your operation. Other land-forming systems are only operational 75 percent of the time, which means you get fewer working hours and higher costs. But Trimble’s grade control system integrates with the Trimble® FieldLevel™ II System and gives you faster, more accurate results. By using ground-breaking technology, it operates at 95 percent uptime in even the most challenging environments.

With it, contractors get increased uptime and a reduced number of passes needed to complete a job. And, farmers can benefit from fields that have better water management and crop yield.

But the path to proper water management and higher crop yields begins with your soil. Soil type can heavily impact its ability to retain moisture and deliver it to the crop. While clay soils are great at retaining water, they are also heavy and sticky. On the other hand, sandy soil drains well with high hydraulic activity and percolation. But if you want to produce consistent yields throughout your field, you need to appropriately space tile laterals throughout the entire field in order for it to drain properly.

Hardware solutions like the FieldLevel™ II System streamline surveying, designing and leveling required for land-leveling projects. It also helps ensure optimal water management by providing you with improvements in yields, water usage and farm productivity.

Data Integration

If there’s any real magic in PA, it’s found in data integration.

As you’ve read above, there’s no shortage of data that growers can collect, whether it’s yield maps, soil test results or input costs. However, the real power of PA is unleashed when all that data is combined to provide you with a complete story of your operation. But, that’s easier said than done, and in many ways, integration is one of the hardest things to get right in PA.

5 Ways to Get Better Data Integration

The basic goal of PA data integration is to organize all your farm data in useful ways for analysis and decision-making. Here are five things you can do to help make that happen:

-

-

-

-

- When you purchase any new software or hardware for your farm, make sure it’s compatible with what you’re already using. If the systems don’t work together, then it won’t give you the results you’re looking for. But, if you’re using ISOBUS technology, you won’t need to worry. ISOBUS technology is the industry-standard to achieving compatibility between tractors and implements by following a ‘plug and play’ mandate. You no longer need a separate or brand-new display system for each tractor, as it allows for both display and machine to speak to each other, regardless of brand or age. ISOBUS equipment like the ISOBUS-compatible GFX-750™ Display or the Field-IQ™ ISOBUS Control Solutions keep you connected to every piece of software and hardware.

-

-

-

-

-

-

-

- Make sure you regularly calibrate and service your technology solutions just like you would with your equipment. Take the time to get to know the technology you’re using, and you’ll save yourself time and money down the road.

- Investigate high-speed Internet options for your farm—both in your office and in the field. If possible, the benefits of having a high-speed Internet connection in the cab might be worth the investment to help with in-the-moment decisions in the field.

- Explore online data storage. All those USB sticks that you’ve got in drawers in your office are nice backups for your data, but they aren’t as effective or practical compared to storing it all in one place online. Online or ‘cloud’ storage space is getting cheaper and safer all the time and allows you to easily share with your accountant, farm advisor, insurer or lender. And remember—it’s your data—and you have the right to know how it’s being used by your operation’s stakeholders.

- Partner up with an expert. While hardware and software solutions are becoming more compatible and easier to use, it’s still an intimidating task to get them all working together. A Trimble Vantage Reseller is an invaluable resource to have, especially when getting started, to make sure all your PA data is integrated and getting you the information you need to make the best decisions for your farm.

-

-

-

Correction Services

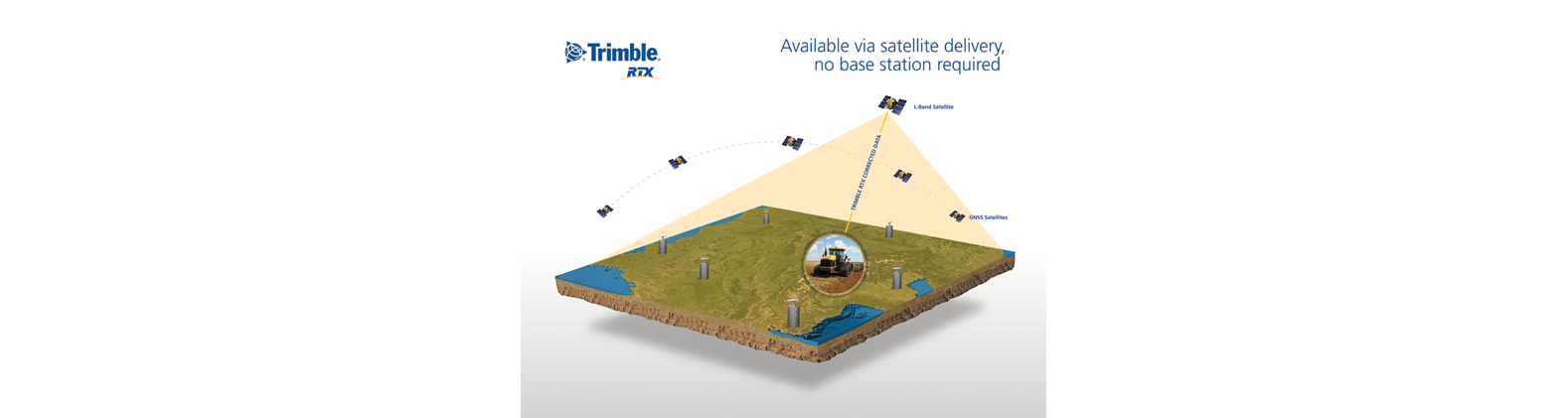

When thinking about accuracy and getting the most out of your operation, correction services are an important point of consideration. Many farmers benefit from higher levels of accuracy available from providers like Trimble. These advanced-positioning services give you access to innovative positioning services tailored to fit the accuracy level that’s right for your operation. From sub-inch to sub-meter accuracy needs, our intelligent solutions drive precision ag success.

As an example, CenterPoint RTX satellite-delivered correction services, provides high accuracy positioning better than < 2.5 cm and offers built-in redundancy to ensure connectivity, consistency and quality for less cab time, tighter rows and straighter lines. CenterPoint RTX also provides corrections for all GNSS constellations, taking full advantage of all supported GNSS constellations, including Galileo and BeiDou. Using these additional satellite signals, the CenterPoint RTX provides faster RTX convergence times and more robust performance under natural obstacles such as trees. Customers may experience up to 40% faster convergence times when additional satellites are used for CenterPoint RTX. Trimble RTX correction services are repeatable pass-to-pass, season-to-season and year-to-year for achieving high accuracy positioning for your guidance system and precision farming needs.

The Future

Traceability, instant weather reporting and up-to-the-minute commodity market information are all data sets that are rapidly being addressed by the latest PA software solutions—with the aim to receive and send this data automatically and instantaneously from the tractor or your office.

A scenario in the not-too-distant future might look something like this: You’re seeding your field and the weather forecast changes to a much-needed rain. With this new information, you increase the fertilizer rate to take advantage of the added moisture in the soil. Because your cab is web-enabled, this adjustment is automatically reflected in your fertilizer order sheet, cash flow, yield projections and your marketing plan. There’s no need for any extra data entry or office work—your entire operation is integrated and automated.

Increased data integration will not only help you focus on growing a crop, but growing the best possible crop. Technology, agriculture, food—these are industries that are always changing, and Trimble is keeping pace.

The Precision Ag Farm of the Future

Our vision of this concept is simple. It’s one where you have the right technology to solve your day-to-day problems, enhancing your farming operation and your life. The ongoing integration of technology on your farm allows you to turn your precision ag equipment into true decision-making tools for your business. That’s the ultimate goal of precision agriculture.

You’re not alone — it happens all the time. But with the information at your fingertips, it doesn’t have to. By capturing the right farm data, and then leveraging the right

You’re not alone — it happens all the time. But with the information at your fingertips, it doesn’t have to. By capturing the right farm data, and then leveraging the right

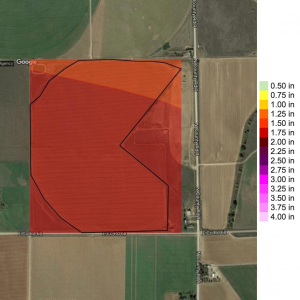

As you can see with this map, farmers get specific information about damaged areas right in their inbox with Trimble Ag Software’s Hail Alerts. By seeing a hail coverage map overlaid on their field boundaries, farmers know the precise location and size of hail. This information can save them time and money when scouting fields to assess the damage.

As you can see with this map, farmers get specific information about damaged areas right in their inbox with Trimble Ag Software’s Hail Alerts. By seeing a hail coverage map overlaid on their field boundaries, farmers know the precise location and size of hail. This information can save them time and money when scouting fields to assess the damage.